|

|

|

|

Central EngineeringQuality Assurance Laboratory |

||

|

|

Overview:

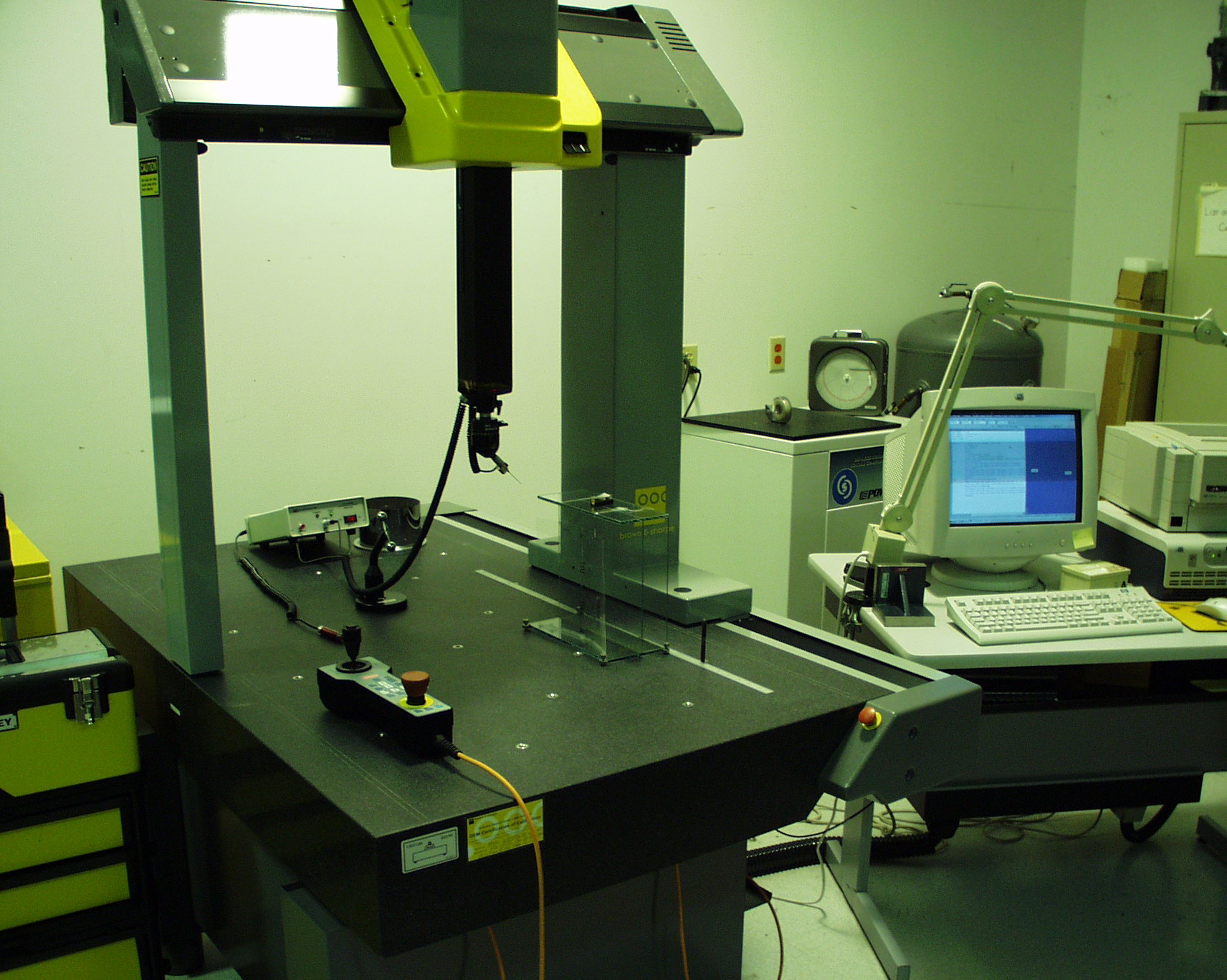

Quality Assurance engineers and technicians, working in a dedicated mechanical inspection laboratory; utilize a range of sophisticated metrology tools to ensure that both custom fabricated and off- the-shelf mechanical hardware components conform to specified requirements and tolerances.  Browne and Sharp Mistral 700 Coordinate Measuring Machine, located in a Class 100 Clean Tent. The CMM has a .0001 tolerance over a usable envelope of 24"x 16"x 30". The machine is fully programmable, and utilizes the same electronic files released for fabrication to measure a completed part to determine its accuracy to the specification.

Browne and Sharp Mistral 700 Coordinate Measuring Machine, located in a Class 100 Clean Tent. The CMM has a .0001 tolerance over a usable envelope of 24"x 16"x 30". The machine is fully programmable, and utilizes the same electronic files released for fabrication to measure a completed part to determine its accuracy to the specification.

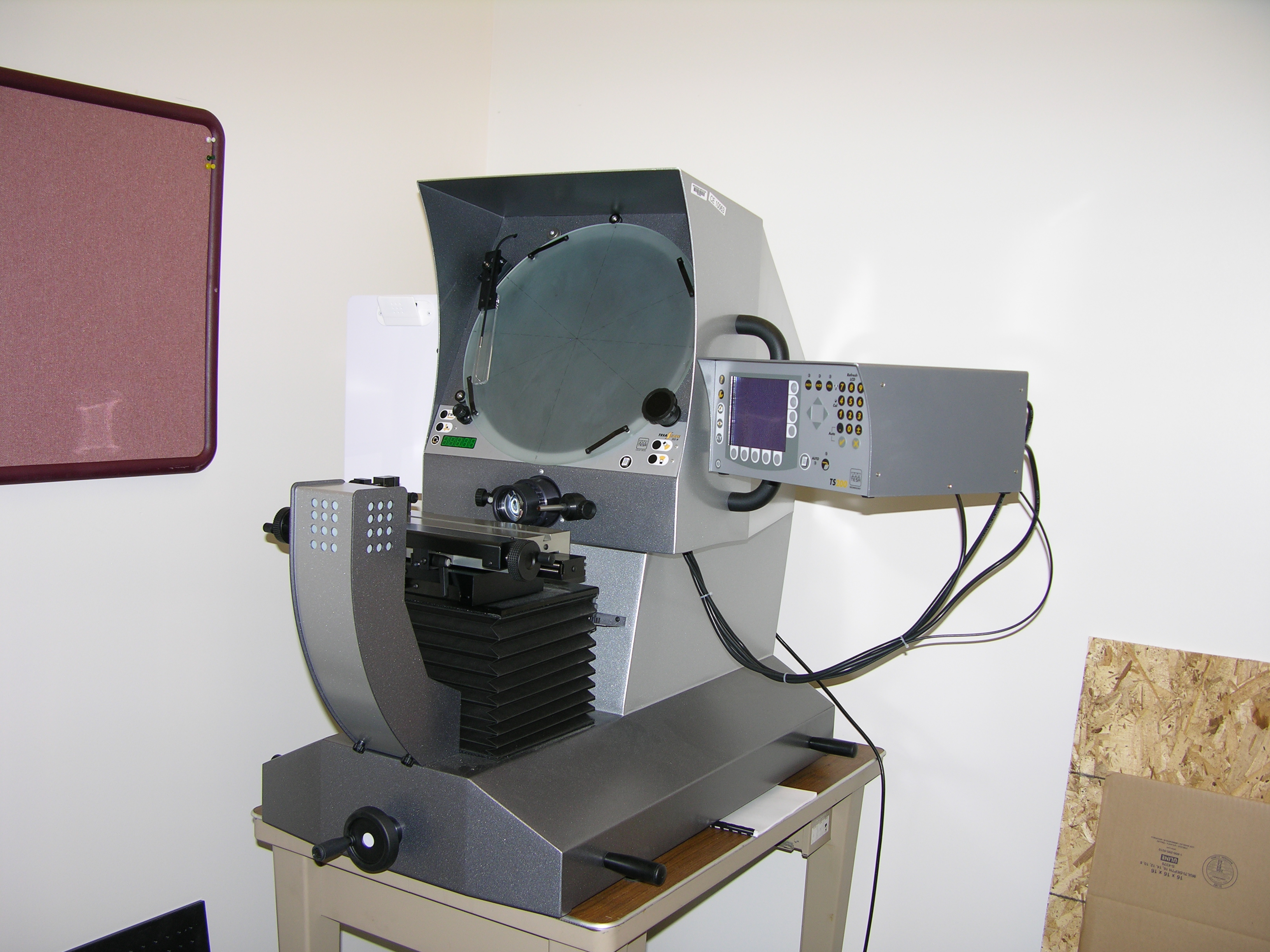

Hardness Tester and Programmable Video Inspection System, including 100 x magnification optical/digital microscope for parts inspection

Hardness Tester and Programmable Video Inspection System, including 100 x magnification optical/digital microscope for parts inspection

Additional resources include:

Quality Assurance Laboratory Point of Contact:

Ranjani Srinivasan (617) 495-7104

To return to the Main Laboratory Page (Click Here) |

|